Photos of Reflux Stills

Theres quite a variety of general reflux stills about.| Marty's Still | ||||

| ||||

| Peter's Still with Vodka Bottle Condenser | ||||

|

It is set up in "ambient reflux" mode in

the first picture. The column is 1.7m. It can be turned into a vapour management still by putting my vodka bottle on top, and a gate valve in the horizontal outlet. The keg was very roughly angle grinded. it has a series of M6 studs welded onto the top, a flange fits over these and is held on with nuts. I cut the bottom off the smirnoff bottle by wrapping some masking tape around it near the bottom. Then I used a normal steel file to score a line around the bottom using the masking tape as a guide. You have to go slow at first since the file tends to slip. Once you have filed a small bit you dont have to be so careful as the file slips into the groove easily. Then i heated the bottle by sitting it directly on my cooker hot ring for a few minutes and then quenching it in cold water. Those vodka bottles are very tough and it took a few quenchs before the base fell off. I have used a glass cutter too, but find the file easier. On the forums somebody mentioned using a vibrating metal engraver. nearly everybody will have a file though. I have cut wine bottles without scoring the bottle at all, just heating and quenching, about 1 in 4 bottles cracks correctly. The broken bottle should be sanded/filed down to prevent cuts. it is great to be able to see the reflux in action. That photo is of it actually running but i think the camera shutter speed was to slow to capture what was going on. the column is s/s at the 2 ends and has a copper centre piece about 1.4m which the s/s tubes slot into to make a perfect fit. It has 20 s/s scrubbers. It is insulated with a large cardboard carpet roll which is stuffed tight with glass fibre attic insulation inbetween the gap of the cardboard and the column. What you cant see in the photo is the plumbline i have on the column, i put cardboard under the sides of the keg until the column is perfectly vertical. |

|

| ||

| Dom's Still | ||||

|

I have constructed my own offset head still. The unit breaks down for easy storage, cleaning and transport. I have plans for a bigger boiler as this one is less than 19L. | ||||

| ||||

| Tim J's Still | ||||

| ||||

| Ken & Mikes Project | ||||

| We get 2.7L from a 23 L, 10.7% mash. It is 91% Mike : We polished with activated charcoal and used caramelized sugar for colour and oak toasted oak chips are in the diluted (52%) product for the vanillans. I insulated the boiler to make it more efficient (around the pot and a round piece on top of the pot,as per picture).I also insulated the colomn with 2 pieces of insulation that are fit for a 1" pice of copper pipe.(one piece per side...look at the picture).By the way...I use 7 brass scrubbers from Zehrs market in my column and they impart no extra flavours!!! When rolled out between the hands...the scrubbers are about 5" long and 2" in diameter. Put them into the column slowly and carefully!!! (also see Mikes recipe for Capt Morgans Spiced Rum) | |||

| Ken :

Pot Temperature: Measured on the lid for a better idea of the steam temp as

this is the portion that is most critical. By keeping the temperature

between 198-206 degrees F (92-96C), we are able to tell when the wert is getting too

hot and giving us that 'Brackish' smell that can be calmed with carbon

filtering but never quite goes away. Now, Mike and I have slightly

different opinions on the tails aspect but we do agree that the burning of

the wert is what was making the first few batches of rum a little on the

unpalatable side. We bit the bullet and drank it anyway but with the new

numbers, we have made a very flavourful rum product. Final flavouring with

cloves and cinnamon will be the defining bit. When the lid temp reaches

208F (98C), shut down the still. I know, there is more to come but I found a +4

degree variation between the lid and the boiler body. As soon as the boiler

body hits 212 (100), the wert started to burn and that... smell... came through

into the product. Variac: Because we are using 2/1500 watt heating elements from a water tank for heat up, we get to temperature on 23L in about 45 minutes. At that point, we switch to one heater only (all that is needed to maintain the temp now) on variac control at 105-107 vac. Kinda like using a stove rheostat at 9 instead of 10. This slows the heating of the pot to get a longer run and as the alcohol is boiled off, the temperature climbs. We don't do a full boil all the way through, just a slight rolling. We also found that we only needed 2 scrubbies (teased until they cried) in the column you see in our picture. We had added some more but it took quite a bit of heat to get a flow. We clean distilled water with nothing in the column and decided that less is more. To help the reflux happen quicker without losing too much in percentage, ( about 5% ) we didn't have to run quite as warm and ended up with a smoother result. We will add 1/2 of a scrubby for the next boil but we are on the right track for us. Keep in mind that these scrubbies have been pulled almost to the length of the column and allowed to coil back on themselves. This, it would seem, gives us the same area as the rashiq rings. | ||||

| http://ponu.haisee.com/ | ||||

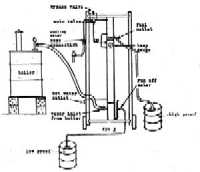

| Reima tells me ..."there is a neat still at http://ponu.haisee.com/

only it is in my old lingo so I have translated it hoping the owner

does not mind.

It should tickle the minds of those who like to play with thumpers,

cause it seems to have one built in." Lower colon is 300-400mm high. Top one is 250mm. Red tube of 8mm and blue of 10mm copper. This does a double distilling in one go, like a built in thumper, and is self tuning. Only critical tuning needed is cooling water flow. Steam goes through "A" and condenses on its way back to lower colon coil made of 8mm by about 1m length copper tube. In this coil, being in the path of about 90C vapours a new boiling of distillate occurs. At the bottom of this coil there must be a 50mm liquid lock (a bend up). The lighter ethanol in this coil boils and travels up to the T piece and to the condenser, the heavier stuff runs back to the boiler through the liquid lock. Both colons are of 60mm outside diameter SS-tube Lower colon is 350-400mm and top one is 250mm length. Coils of 8mm copper tube. Tube A 10mm and B 8 mm tube. This works on a 20 litre boiler heated with a 1 kW heater. Condenser coil length is not critical 0.5m length is enough. Highest pressure in this system is then 50mm water height. When tube A is starting to warm up it is time to let in some cooling water, only little. It should not run out as thick as a match stick, if too much cooling there will not come out anything. Try to keep the top colons lower part hand warm when its upper part is hot. And remember the slower it comes out the stronger it is. | |||

| Scott's POS Firewater Hook Column & Flamethrower Condenser email: goyeast@yahoo.com | ||||

| ||||

|

This is my column and condenser, assembled

minus the tubing. It achieves total reflux by

default, and the distillate is drawn off via the gate

valve. I've since added a needle valve below the gate

valve in order to achieve finer control.

With a 750 watt element, I've drawn 400 ml per hour of

95%+ alcohol, which isn't very fast, but I just

purchased a 1500 watt element that will probably

increase this significantly. The column is 45 in. x

1.5 in. and is packed with s.s. pot scrubbers.

The condender assembly is 44 in. long, with the

jacketed portion being 26 in. x .75 in. around a .5

in. pipe (a lot longer than necessary, I've found). I've only had two issues with this design. 1) The condenser screws onto the column, thus in order to draw off alcohol, I need to wrap the column's male fitting with PTFE tape to insure that the take-off valve is pointing toward the ground. 2) When assembled, the column and condenser need to be stablized. I use a homemade wooden frame which has worked well. | ||||

| Pilch's Stills | ||||

| ||||

| Purity : 92% | ||||

| Smithers Still at http://go.to/distil | |

| Smithers says ..

Packing type : stainless pot scrubbers Distillate flowrate : approx 600-700ml/hr @ 95% purity Pot capacity : 30 ltr urn approx construction cost in aussie dollars .. temp controller cost about $60 to make still head materials (stainless) cost about $15 element (1.38kw) cost $40 one carton of beer to the welder $20 dig temp probe $18 urn $20 at an auction The controller will switch 3.0kw so theoretically you wouldn't need to use the 1.38kw element but I like a speedy heat up |

Construction details/tips :

| |

| Jan Willem at http://www.geocities.com/homedistilling/ | |

| Column is 115cm long and 42 mm diameter packed with stainless steel scrubbers

Output is about 500 mL/hour at 94% purity See Jan's site for heaps of details re construction and design options. |

| The coil (for reflux) is made of 10mm soft copper, easy to wind but really inefficient to use. The coil has 12 windings and needs massive amounts of cooling water to keep the top cool enough for sufficient reflux. A innerside coil is much better, even pass trough pipes AT THE TOP! are better, but i don't like these because I want my column to be clean and empty on the inside. That means NO pipes coils or other things in the column, now I can experiment with lengths and so, it also makes it multi functional. U can turn it with a short EMPTY column into a potstill etc I'm experimenting with a new cooling thing a (sort of) drawing is atached to this message. I hope you get the idea.... |

| Homer's still (Hillbillyman50@hotmail.com) | ||||

|

Diameter : 3.5 inches Reflux Column Height : 16 inches Reflux Column Packing : stainless steel pot cleaners Heat input : High on my electric stovetop Purity : 92% to 93% depending on how much reflux Flowrate : 92% at 350 ml hour and 93% at 250 ml hour (give or take little bit) Still : 4 Gallons I have five cooling coils 3/4 of the way up the column. The approximate cost was $175.00 To $200.00 The Stainless Steel valves, tubing, pipe & fittings were very expensive but it was well worth the cost for an easy to clean still. The gasket between the lid and the pot is Tygon tubing it is heat and chemical resistant. You can't see it on the photos because it was not on the pot when the photos were taken. It is very easy to clean the column. Diagram of how to make & fit the coils inside the column

| |||

I just finished my first run through my new all stainless steel

reflux still. The spirits was a very very clean 95+%. The boiler is a

10 gallon tank and the reflux column is 2" ID and 48" tall with

stainless steel pot scrubbers. I have two 2000W elements for fast

heat up. When the wash is up to temperature I can cut off one of the

element and can regulate the wattage on the second element to

maintain the correct temperature in the reflux column. This is my

second still and they work well.

| | |||

| Ted's Still at http://mwci.s5.com/ | ||||

| This still is built from materials from the local hardware store.

All of the plumbing is standard copper plumbing pieces. The kettle is a 5 gallon

canning kettle. The top is held on with spring clips, and flour paste provides

a good seal. The still can be disassembled easily for cleaning. The column

is a 1 inch copper pipe filled with copper pot scrubbers. Above this is a

short reflux condenser. The only tools needed to build this were a propane

torch, pipe cutter, screw driver, and dremel tool with a grinding bit. From an 8% wash, I get 94+% at 600ml/hour. It will run like that until the alcohol is nearly gone from the wash and then the flow drops off and the temperature starts to rise. At this point I kill the reflux and collect tails to 96 C. Here you can see the reflux condenser jacket which is made out of a 1" T. There is a small plastic tube inside the one that you can see, that goes over to a point in the main condenser. So, even though it looks like the there is only one port for cooling water there is actually a flow through it. | |||

| Robert Warren's "Charles 803" at http://running_on_alcohol.tripod.com email robertwarren@mail.com | |

| This is a fuel alcohol still, designed to be a higher volume still, allowing you to run 50 to 100 gallons of mash at a time and make enought ETOH to fill your gas tank. |

| Marks's Still | ||||

| Purity : 95 % | |||

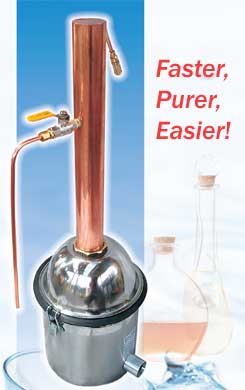

| The Ultra Pure Still at www.puredistilling.com | |

|

Purity: 95% 100% Money Back Guarantee Using just a 25cm column, this still produces 2 bottles of spirits from its 5L boiler in just 30 minutes, including heatup time! It uses a 2200W element, and amphora structured copper mesh for smooth, authentic flavour. Comes with a digital thermometer for accurate cuts. A true reflux still for an excellent price - just $467 delivered anywhere in the world - guaranteed. |

| http://homedistiller.org This page last modified |